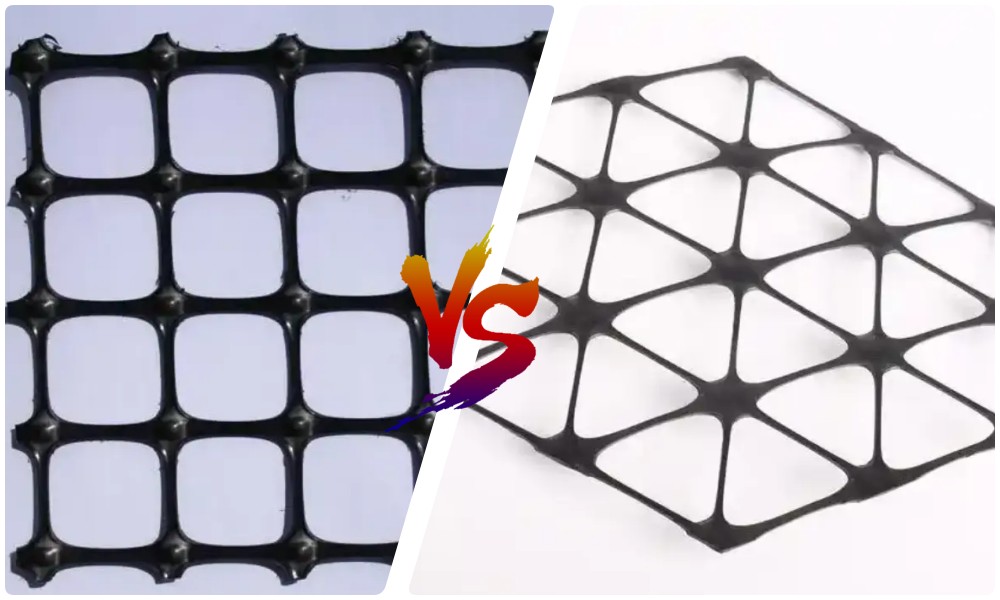

◆ Biaxial Geogrid

Produced via polymer extrusion, sheeting, perforation, and bidirectional stretching, forming a high-tensile network in longitudinal/transverse directions15.

◆ Triaxial Geogrid

Manufactured with additional Z-axis stretching after biaxial processing, achieving three-dimensional reinforcement capabilities2.

Mechanical Properties Comparison

| Parameter | Biaxial Geogrid | Triaxial Geogrid |

|---|---|---|

| Tensile Strength | 80-120 kN/m (XY-axis only)1 | Balanced strength in all axes2 |

| Stiffness | 40% stiffness increase in base1 | Superior multidirectional rigidity2 |

| Elongation | ≤10%1 | Enhanced deformation control2 |

Road Engineering Applications

● Biaxial Advantages

- Load Distribution: Reduces stress concentration via XY-axis load transfer14

- Settlement Control: Cuts uneven settlement by 2/3 in soft soil13

- Cost Efficiency: Ideal for rapid deployment in embankments/slopes56

● Triaxial Advantages

- 3D Reinforcement: Maintains integrity under complex geological stresses27

- Adaptive Performance: Excels in high-fill areas & existing road upgrades24

- Longevity: Extends pavement life through elastic deformation management2

Construction Requirements

| Factor | Biaxial | Triaxial |

|---|---|---|

| Precision | Standard overlap control6 | Strict 3D alignment needed2 |

| Flexibility | Simple installation5 | Adapts to variable loads2 |

| Site Conditions | Stable terrain3 | Complex geology compatible7 |

Selection Guidelines

┌───────────────────┬───────────────────────────────┐

│ Engineering Needs │ Recommended Geogrid Type │

├───────────────────┼───────────────────────────────┤

│ Time-sensitive │ Biaxial (rapid deployment) │

│ High-fill sections│ Triaxial (3D stabilization) │

│ Soft soil bases │ Triaxial (settlement control) │

│ Budget constraints│ Biaxial (cost efficiency) │

└───────────────────┴───────────────────────────────┘

│ Engineering Needs │ Recommended Geogrid Type │

├───────────────────┼───────────────────────────────┤

│ Time-sensitive │ Biaxial (rapid deployment) │

│ High-fill sections│ Triaxial (3D stabilization) │

│ Soft soil bases │ Triaxial (settlement control) │

│ Budget constraints│ Biaxial (cost efficiency) │

└───────────────────┴───────────────────────────────┘

Decision matrix based on technical specifications and cost-benefit analysis