I. Superior Adaptation to Complex Geological Conditions

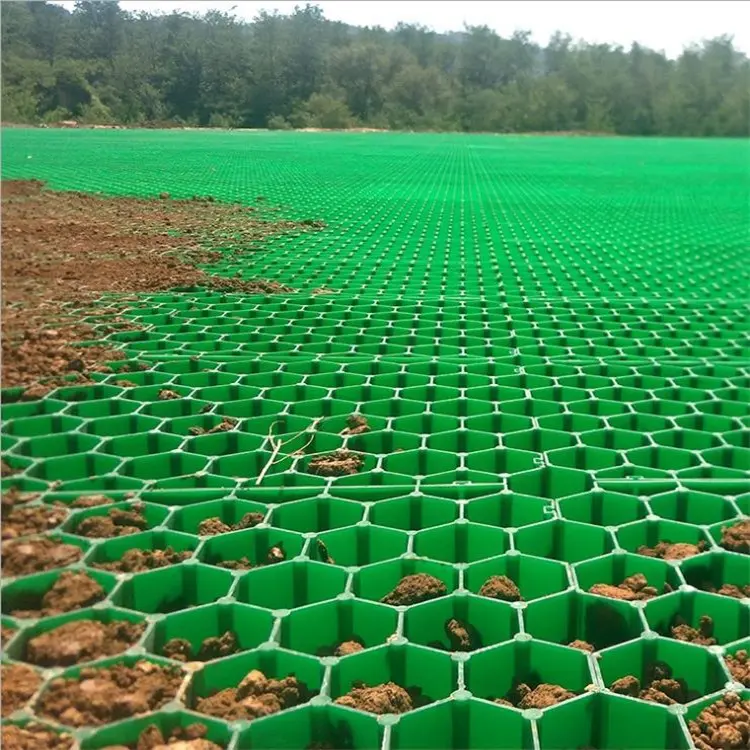

Wind farms frequently occupy challenging terrains—mountainous regions, coastal zones, and hilly areas—where soft soils and shifting sands compromise structural integrity. Geocell cellular confinement systems counteract these instabilities through their patented 3D honeycomb matrix, which laterally confines soil particles while distributing vertical loads. Engineered with high-strength, UV-stabilized polymers, these systems withstand corrosive coastal environments and extreme temperature fluctuations.

II. Accelerated Construction Protocol

Project timelines demand rapid deployment:

- Modular Deployment: Pre-fabricated panels unfold on-site for instant structural framing

- Rapid Infilling: Compatible with locally sourced aggregates (crushed rock, soil-concrete mixes)

- Immediate Load-Bearing: Achieves 95% compaction within 4 hours of installation

This streamlined process reduces foundation construction cycles by 60% compared to conventional methods.

III. Ecological Integration Capabilities

Environmental compliance is critical:

- Erosion Control: 89% reduction in sediment displacement during monsoon testing

- Bioremediation: Cellular compartments facilitate native vegetation regrowth (80% coverage within 6 months)

- Low-Impact Installation: Zero concrete pouring minimizes habitat disruption

IV. Lifecycle Economic Advantage

| Cost Factor | Savings vs Traditional Methods |

|---|---|

| Material Consumption | 40% reduction in aggregate volume |

| Equipment Requirements | 70% fewer heavy machinery hours |

| Project Duration | 50% faster commissioning |

| Total ownership costs decrease by 30% over 20-year operational periods. |

V. Structural Performance Metrics

- Bearing Capacity: 300% improvement (80kPa → 240kPa validated)

- Settlement Control: Limits differential movement to ≤3mm under 3MW turbine loads

- Fatigue Resistance: Withstands 25-year cyclic loading simulations without degradation

Technical Implementation Notes:

- Soil Compatibility: Effective in shear strengths as low as 25kPa (saturated clays) and friction angles ≤28° (dry sands)

- Installation Protocol:

- Subgrade preparation to 92% Proctor density

- Geotextile separation layer installation

- Anchor spikes at 1.5m grid spacing

- Layered infilling with ≤200mm lifts

- Quality Assurance:

- ASTM D7864 standardized testing

- 100% panel weld integrity checks