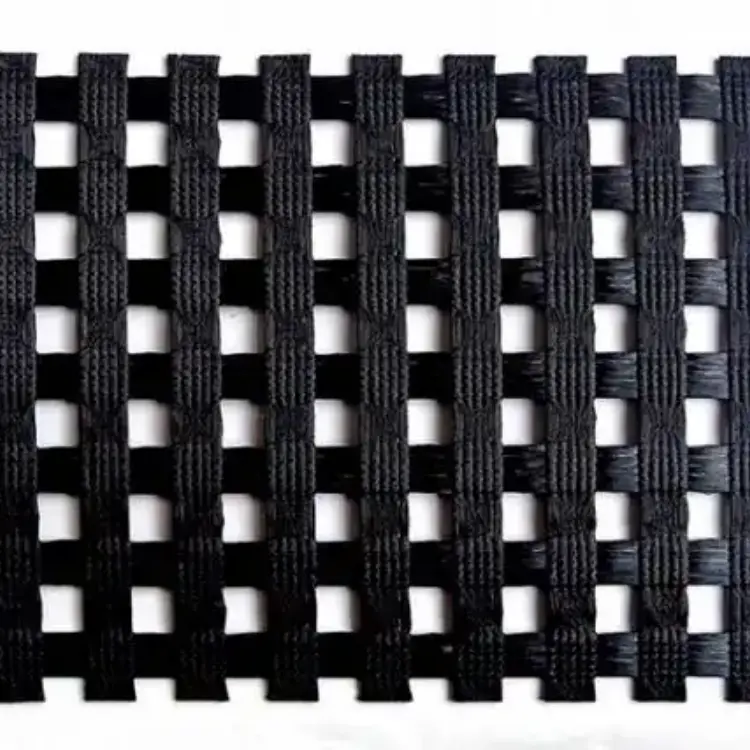

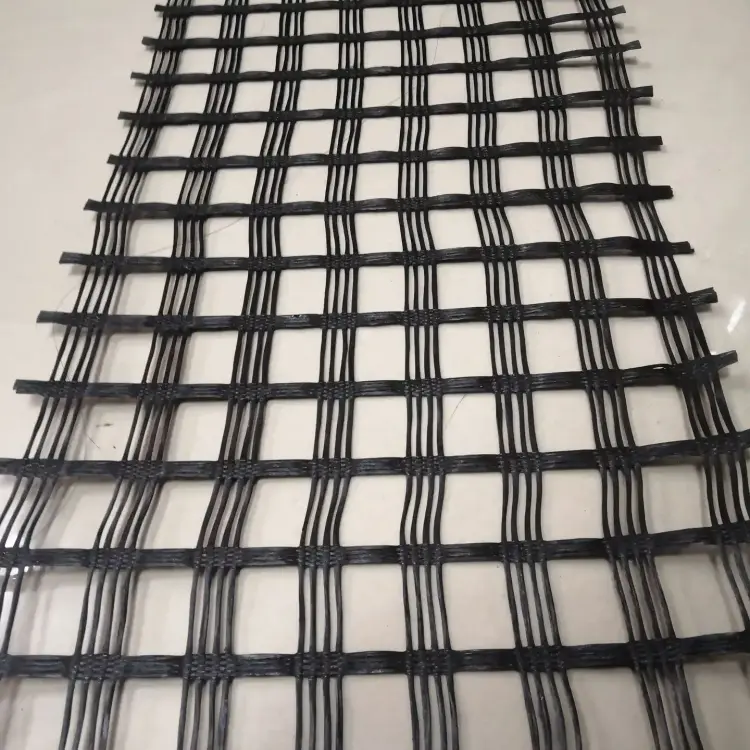

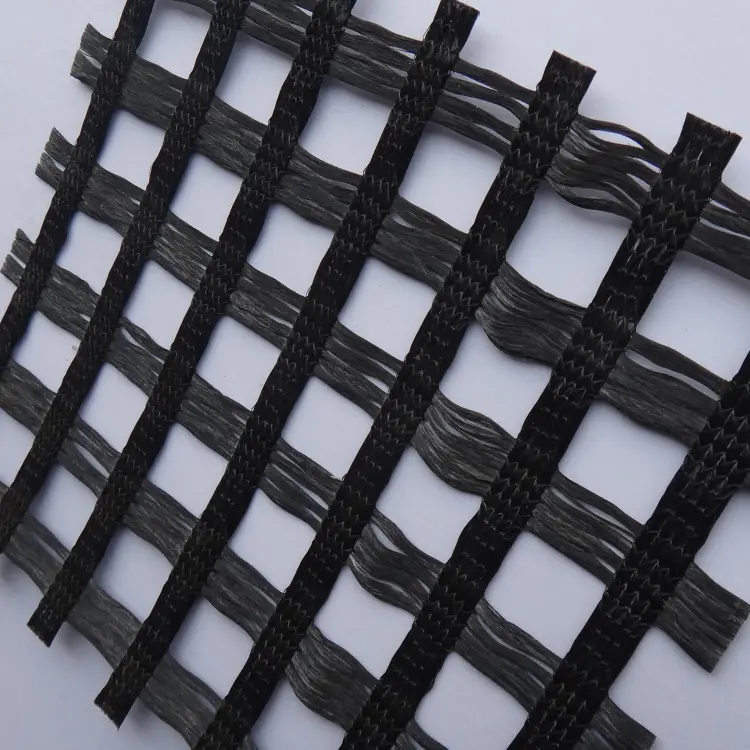

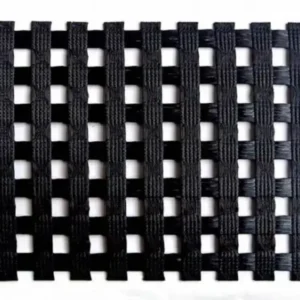

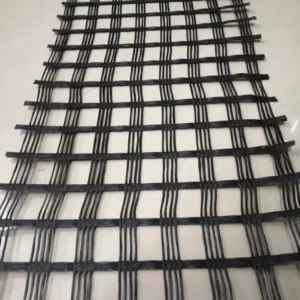

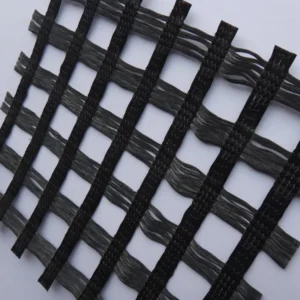

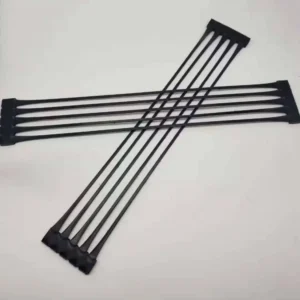

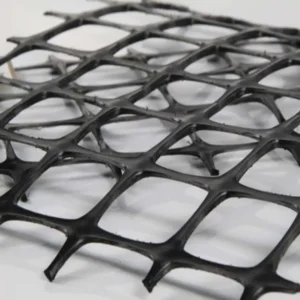

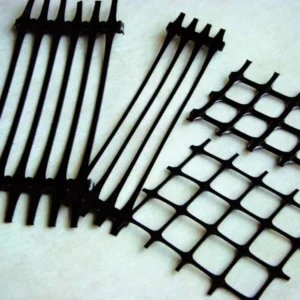

Fiberglass geogrids are woven or knitted geosynthetic materials composed of fiberglass yarns coated with polymer (typically PVC or asphalt). Unlike conventional plastic geogrids, they offer:

- Zero creep deformation under sustained loads

- 2-3x higher tensile strength than polyester alternatives (up to 300 kN/m)

- Exceptional chemical resistance to pH 2-13 environments

Fiberglass Geogrid Standard Sizes

| Parameter | Roll Format | Panel Format |

|---|---|---|

| Width | 1m / 2m / 3m / 4m / 5m / 6m | 1m×1m / 2m×2m / 3m×3m |

| Length per Roll | 50m / 100m (standard) | N/A (pre-cut) |

| Aperture Size | 20mm×20mm / 25mm×25mm / 30mm×30mm / 40mm×40mm | Same as roll format |

| Thickness | 1.0mm / 1.2mm / 1.5mm / 2.0mm | Matches roll specs |

| Tensile Strength | 50kN/m / 100kN/m / 150kN/m / 200kN/m / 300kN/m | Customizable |

Primary Applications

- Asphalt Pavement Reinforcement

- Reduces reflective cracking by 60% (AASHTO TP-114 verified)

- Soil Stabilization

- 40% higher bearing capacity vs. unreinforced subgrades

- Mining & Heavy Industrial Zones

- Withstands dynamic loads up to 10,000 cycles at 50kPa

Why Choose Our Fiberglass Geogrids?

- Customizable mesh patterns (uniaxial/biaxial)

- UV-resistant coatings with 25-year warranty

- Third-party certified by CE, ISO 9001, and AASHTO

Available in standard rolls (4m×50m) or project-specific dimensions.