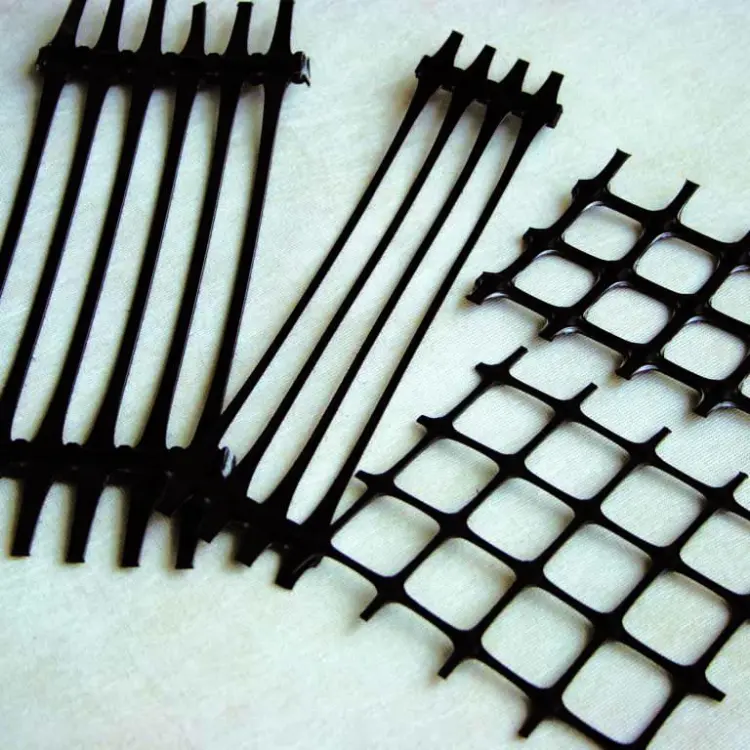

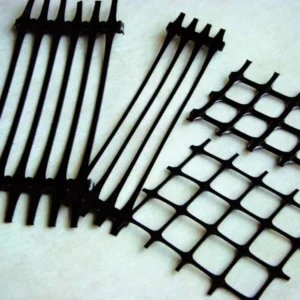

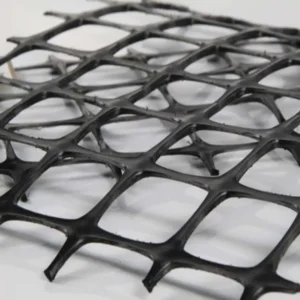

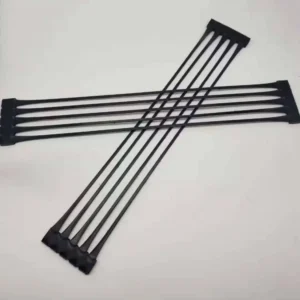

Geogrid for retaining walls are polymer-based tensile reinforcement materials designed specifically for mechanically stabilized earth (MSE) retaining walls. Our biaxial and uniaxial geogrids transform ordinary soil into a structural mass through particle interlock, providing superior stability versus conventional concrete walls.

Key Technical Advantages

- Material Science

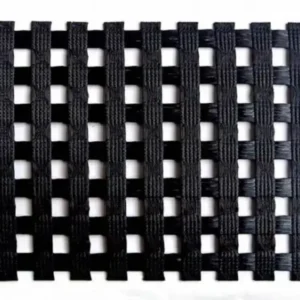

- High-density polyethylene (HDPE) or polyester (PET) construction

- UV-stabilized formulations (ASTM D4355)

- Tensile strengths from 20 kN/m to 400 kN/m (ASTM D6637)

- Performance Metrics

- Aperture sizes: 25–100 mm for optimal soil interlock

- Junction efficiency >90% (critical for load transfer)

- Creep resistance: <2% strain @ 50% ultimate load (10,000-hour tests)

- Design Flexibility

- Modular installation accommodates complex curves

- Reduces required excavation by 40% vs. concrete walls

- Compatible with all backfill materials (AASHTO M288 Class I/II)

Comparative Benefits

ParameterGeogrid WallsConcrete Cantilever WallsConstruction Speed3–5x fasterSlow formwork processesCost per m²$60–$120$200–$400+Design Life75–100 years50–75 yearsEnvironmental Impact60% lower carbon footprintHigh cement usage

Installation Protocol

- Subgrade Preparation

- Compact to 95% Standard Proctor density

- Minimum 300mm leveling layer

- Geogrid Deployment

- Unroll with machine direction perpendicular to wall face

- Maintain 1%–2% slack for soil interaction

- Connection Systems

- Proprietary polymeric connectors (500+ cycle durability)

- Metallic strips for high-load applications

Global Compliance

- ISO 10319:2015 (Wide-width tensile testing)

- EN 15381 (European harmonized standards)

- FHWA-NHI-00-043 (US federal guidelines)

Case Study: Colorado Highway Project

- 14m tall reinforced wall

- 35,000m² geogrid deployment

- 22% cost savings vs. cast-in-place concrete

- Completed 8 weeks ahead of schedule

Note: All technical data represents minimum guaranteed values from third-party certified labs.

Contact Us

Hengshui Aohong Engineering Materials Co., Ltd.

- 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China.

- +86 318 5261 900

- +86-186-3287-9676 (WhatsApp)

- sales@cn-ahjt.com