Introduction

In modern civil engineering, fiberglass geogrids and steel mesh serve as two fundamental reinforcement materials with distinct characteristics. This technical analysis evaluates their properties, applications, and cost-effectiveness based on current industry standards.

1. Material Properties Comparison

1.1 Fiberglass Geogrid

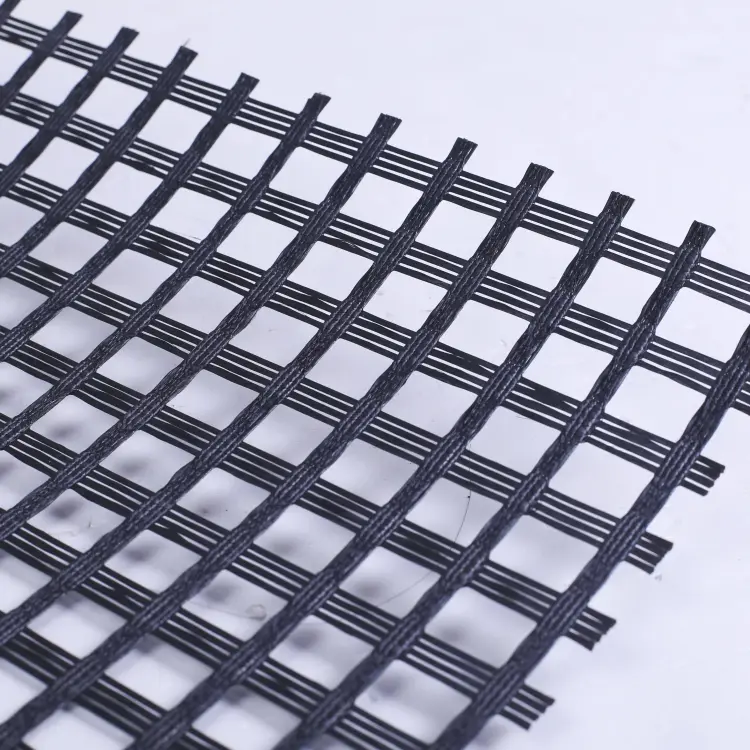

- High Strength & Low Elongation: Exhibits tensile strength up to 160 kN/m with <3% elongation, ensuring structural stability under load.

- Superior Weather Resistance: Inorganic silica composition withstands extreme temperatures (-100°C to 1000°C) and resists chemical corrosion.

- Asphalt Compatibility: Special coatings enhance bonding with asphalt mixtures, preventing delamination.

- Aggregate Interlock Mechanism: Mesh structure improves load distribution by mechanically locking aggregates.

1.2 Steel Mesh

- Conductivity & Customizability: Copper/aluminum variants suit precise PCB designs in electronics.

- Corrosion Resistance: Stainless steel types maintain stability in humid/acidic environments.

- High Precision: 50μm tolerance ensures accuracy in solder paste printing for PCBA.

2. Application Scenarios

2.1 Fiberglass Geogrid

- Road Reinforcement: Reduces reflective cracks by 50% in asphalt pavements.

- Slope Protection: Extends dam/embankment service life by 4-7 years.

- Old Road Rehabilitation: Cost-effectively upgrades aging concrete surfaces.

2.2 Steel Mesh

- Electronics Manufacturing: Essential for solder paste deposition in SMT assembly.

- Component Alignment: Ensures positional accuracy during PCB soldering.

3. Construction & Cost Analysis

3.1 Installation

- Fiberglass Geogrid: Lightweight (0.3-1.2 kg/m²) allows manual laying; requires U-pin fixation.

- Steel Mesh: Demands CNC cutting tools and skilled technicians for PCB integration.

3.2 Economics

- Fiberglass: Higher upfront cost (¥15-30/m²) but cuts long-term maintenance by 30%.

- Steel Mesh: Lower initial price but limited to niche electronic applications.

4. Conclusion

Fiberglass geogrids dominate civil engineering for their durability and load-bearing performance, while steel mesh excels in precision-demanding electronics. Project-specific factors—including budget, environmental conditions, and required lifespan—should dictate material selection.