Material Composition & Manufacturing

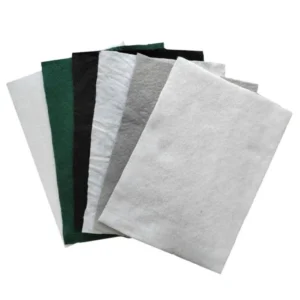

NonWoven geotextile fabrics consist of 100% polypropylene or polyester fibers bonded mechanically (needle-punched), thermally, or chemically. These geotextile non woven fabric exhibit random fiber orientation, optimized for permeability and tensile strength.

Technical Specifications

- Weight Range: 100–800 g/m² (customizable)

- Thickness: 0.5–5.0 mm

- Tensile Strength: 8–40 kN/m

- Permittivity: 0.02–2.0 sec⁻¹ (ASTM D4491)

- Puncture Resistance: 200–1,500 N (EN ISO 12236)

Core Functions

- Separation: Prevents soil layer intermixing in road/railway subgrades

- Filtration: Permits water flow while retaining soil particles (AASHTO M288 compliant)

- Reinforcement: Stabilizes slopes and embankments (e.g., coastal/riverbank protection)

- Drainage: Facilitates lateral water movement in retaining walls and landfills

Key Applications

| Industry | Use Cases |

|---|---|

| Transportation | Subgrade stabilization for highways/railways; concrete pavement interlayers |

| Environmental | Landfill liner protection; erosion control membranes |

| Hydraulic | Coastal revetments; riprap underlayment |

| Landscaping | Weed suppression; root barrier systems |

Performance Advantages

- Chemical Resistance: Inert to soil alkalinity/acidity and biological decay

- UV Stability: Polypropylene formulations resist solar degradation (ASTM D4355)

- Cost Efficiency: Reduces aggregate consumption by 30% in road projects

- Sustainability: Recyclable material with Cradle-to-Cradle® compliance

Quality Certifications

Manufactured under ISO 9001 with compliance to:

- ASTM D4759 (UV resistance)

- EN 13249 (European road applications)

- GRI-GM19 (geomembrane protection)

Contact Us

Hengshui Aohong Engineering Materials Co., Ltd.

- 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China.

- +86 318 5261 900

- +86-186-3287-9676 (WhatsApp)

- sales@cn-ahjt.com