Introduction

Asphalt overlay fabric is a geosynthetic material engineered to extend pavement life by 50-100% while reducing maintenance costs. Installed between old and new asphalt layers, this high-performance fabric prevents reflective cracking, waterproofs roadbeds, and distributes load stresses. Trusted by DOTs and contractors worldwide, it’s the most cost-effective solution for road rehabilitation.

Technical Specifications

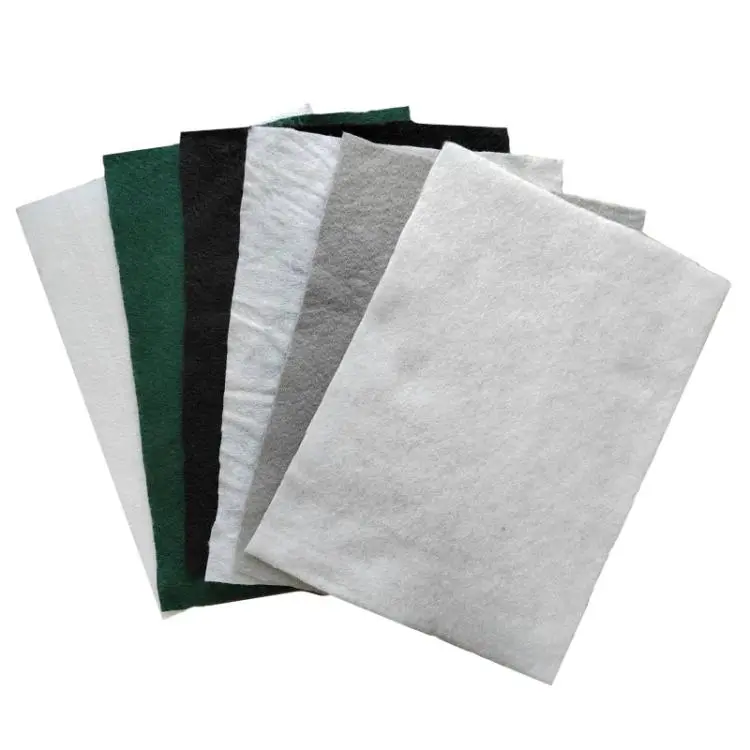

1. Material Composition

- Base Fabric: Nonwoven polypropylene (PP) or polyester (PET)

- Coating: Polymer-modified asphalt saturation (SBS or APP)

- Additives: UV stabilizers, antioxidants

2.Standard Dimensions for Asphalt Overlay Fabric

| Specification | Metric Size | Imperial Size | Tolerance | Notes |

|---|---|---|---|---|

| Width | 1.0m, 1.5m, 2.0m | 3.3′, 4.9′, 6.6′ | ±2% | Custom widths available |

| Roll Length | 50m, 100m | 164′, 328′ | ±1% | Standard commercial sizes |

| Thickness | 1.2-3.0mm | 0.047-0.118″ | ±0.1mm | Varies by material grade |

| Weight | 120-200g/m² | 3.9-6.5oz/yd² | ±5% | Includes saturation |

| Core Diameter | 76mm | 3″ | ±3mm | Plastic/steel options |

3. Performance Benefits

- Crack Prevention: Reduces reflective cracks by 80% (FHWA studies)

- Waterproofing: 0% permeability under 2 MPa pressure

- Temperature Resistance: -40°C to 160°C (-40°F to 320°F)

Why Choose Our Product?

1. Engineering Advantages

- Stress Absorption: Distributes traffic loads evenly, reducing subgrade deformation.

- Bonding Strength: 300% better asphalt adhesion vs. unlined overlays (ASTM D6140).

- Chemical Resistance: Unaffected by road salts, oils, or pH 3-11 environments.

2. Economic Value

- Cost Savings: $3-$6 saved per m² in long-term maintenance (NCHRP Report 747).

- Fast Installation: 5,000 m²/day with standard paving crews.

- Sustainability: 100% recyclable; reduces aggregate usage by 30%.

Installation Guidelines

- Surface Prep: Mill existing pavement, clean debris.

- Fabric Placement: Roll out taut with 150-300 mm overlaps.

- Asphalt Overlay: Apply ≥40 mm hot-mix asphalt within 48 hours.

Note: Compatible with asphalt emulsions or tack coats per ASTM D6998.

Global Certifications

- Quality: ISO 9001, CE Marking

- Environmental: ISO 14001, RoHS

- Transportation: AASHTO M288 Class 1, EN 15381

Contact Us

Hengshui Aohong Engineering Materials Co., Ltd.

- 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China.

- +86 318 5261 900

- +86-186-3287-9676 (WhatsApp)

- sales@cn-ahjt.com