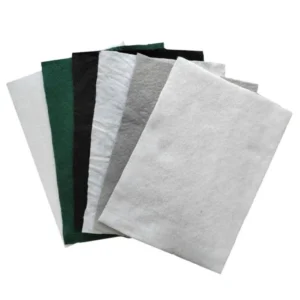

Geotextile road fabric is a permeable polymeric material specifically designed for civil engineering applications. Manufactured from high-tenacity polypropylene or polyester, our woven and nonwoven geotextiles provide optimal separation, filtration, and stabilization in road construction projects.

5 Core Benefits for Road Construction

- Subgrade Separation

Prevents intermixing of soil layers, maintaining structural integrity - Reinforcement

Distributes loads evenly with >50 kN/m tensile strength (ASTM D4595) - Filtration Efficiency

Controlled permeability (10⁻³-10⁻⁴ m/s) prevents soil particle loss - Construction Speed

Roll-based installation reduces labor costs by 30% vs traditional methods - Longevity

UV-resistant formulations ensure 20+ year service life

Project Applications

- Highway base stabilization

- Temporary access roads

- Parking lot subgrades

- Railroad track bedding

- Airport runways

Quality Assurance

All products comply with: ✓ ASTM D4751 (AOS)

✓ ISO 10318 (Geotextile standards)

✓ EN 13249 (European road applications)

Custom widths (2-8m) and strengths available for project-specific requirements.

Contact Us

Hengshui Aohong Engineering Materials Co., Ltd.

- 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China.

- +86 318 5261 900

- +86-186-3287-9676 (WhatsApp)