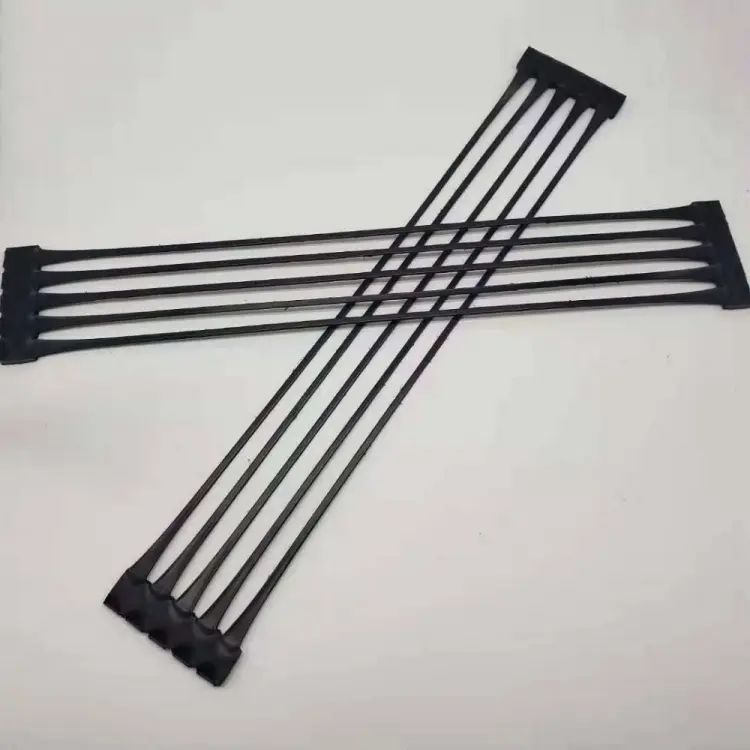

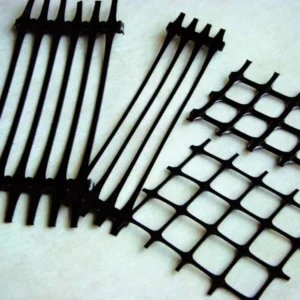

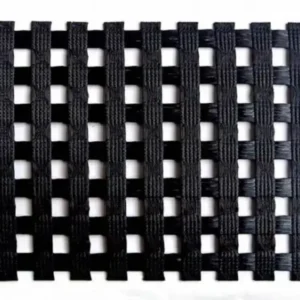

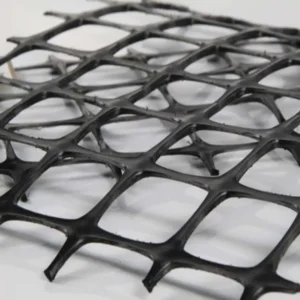

Engineered for high-tensile applications, uniaxial geogrids are the backbone of modern earth retention systems. This polymer-based geosynthetic delivers unmatched strength-to-weight ratios, specifically designed to withstand unidirectional stresses in critical infrastructure projects.

Product Highlights

1. Material Science

- Base Polymer: High-density polyethylene (HDPE) or polyester (PET)

- UV Stabilization: Carbon black/additive packages for 10,000+ hours UV resistance (ASTM D4355)

- Molecular Alignment: Oriented molecular structure achieves 400 kN/m tensile strength

2. Mechanical Performance

PropertyTypical Value RangeTest StandardTensile Strength30-400 kN/mASTM D6637Elongation at Break≤10%ISO 10319Junction Efficiency≥92%EN 15381Creep Reduction<2% @ 50% loadASTM D5262

3. Design Advantages

- Wall Optimization: Reduces required backfill thickness by 40% vs. conventional methods

- Seismic Resilience: Dynamic testing shows <5% strength loss at 0.6g acceleration (FHWA-NHI-00-043)

- Installation Flexibility: Compatible with all major MSE wall facing systems (concrete, segmental, welded wire)

4. Sustainability Profile

- Service Life: 120-year design life (ISO 13437 accelerated aging)

- Carbon Savings: 8.2 kg CO₂/m² reduction vs. concrete alternatives (BRE Environmental Assessment)

- Recyclability: HDPE versions achieve 95% material recovery

5. Project Case Study

Trans-Andean Highway Project (2024)

- Challenge: 45° slope stabilization at 3,800m elevation

- Solution: 180 kN/m uniaxial geogrid with vegetated facing

- Result: Zero maintenance after 5 freeze-thaw cycles

Technical Guidance

Selection Criteria:

- Calculate required tensile strength using FHWA’s Mechanically Stabilized Earth Walls design manual

- Verify soil-geogrid interaction coefficients (pullout resistance ≥1.5 safety factor)

- Specify roll widths to minimize field seams (standard: 2.5-5.0m widths)

Installation Protocol:

- Minimum overlap: 300mm (subject to site-specific validation)

- Connection strength: ≥90% of material strength

- Avoid direct exposure to hydrocarbons or pH <4 environments

Quality Assurance:

- Third-party certification from NAUE, TENAX, or TÜV SÜD

- Batch-specific test reports compliant with CE/UKCA markings

Contact Us

Hengshui Aohong Engineering Materials Co., Ltd.

- 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China.

- +86 318 5261 900

- +86-186-3287-9676 (WhatsApp)

- sales@cn-ahjt.com