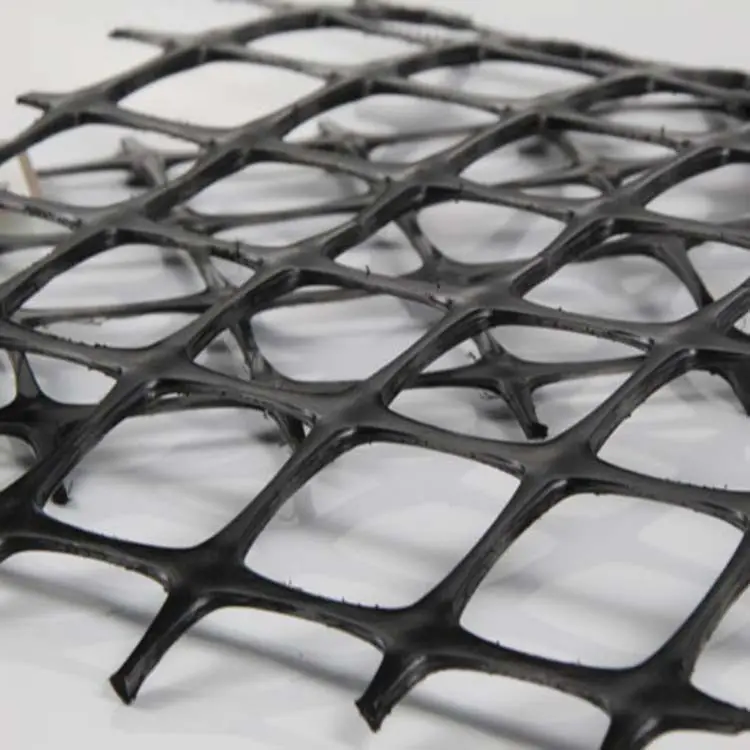

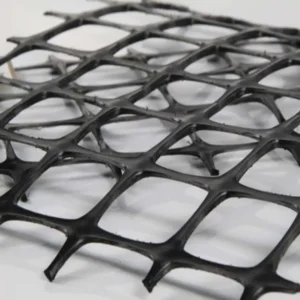

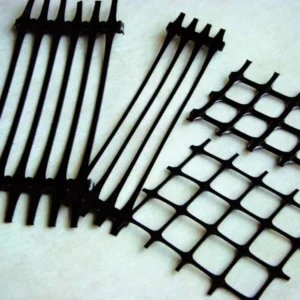

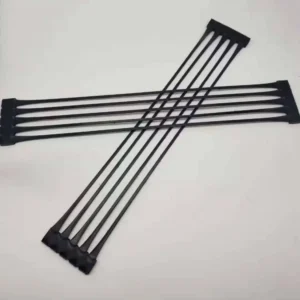

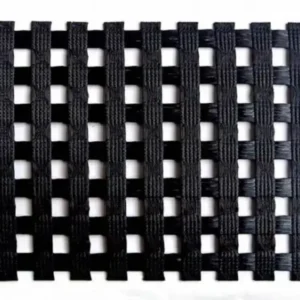

Biaxial geogrids are high-performance polymer grids designed with equal strength in both machine and cross-machine directions. These engineered materials feature integrally formed ribs and apertures (typically 15-50mm) that create optimal interlock with granular soils, delivering superior stabilization for demanding civil engineering applications.

Key Advantages

Bidirectional Load Distribution

- Balanced tensile strength (15-30kN/m in both directions)

- Reduces differential settlement by up to 70%

Enhanced Bearing Capacity

- Increases CBR values by 3-8 times versus unreinforced soil

- Allows construction on soft subgrades (<5% soil modulus improvement)

Cost Efficiency

- Reduces aggregate requirements by 30-50%

- Cuts construction time by 40% through rapid deployment

Environmental Compliance

- 100% recyclable HDPE/PP materials

- LEED-certified projects eligible

Technical Specifications

- Materials: UV-stabilized HDPE or Polypropylene

- Aperture Stability: ≤5% deformation under 2000h creep test (ISO 13431)

- Chemical Resistance: Stable in pH 2-14 environments

- Design Life: 75+ years per EN 15381

Applications

- Base reinforcement for roads/railways (FAA Advisory Circular 150/5370-10G compliant)

- Landfill liner systems (meets EPA Subtitle D requirements)

- Working platforms over weak soils

Quality Assurance

Manufactured under ISO 9001:2015 with third-party certifications including CE Marking and AASHTO M288-17.

Contact Us

Hengshui Aohong Engineering Materials Co., Ltd.

- 161# Ronghua Street, Taocheng District, Hengshui, Hebei, China.

- +86 318 5261 900

- +86-186-3287-9676 (WhatsApp)

- sales@cn-ahjt.com