1. Translate “cost-saving” into “reinforcement”

1. Translate “cost-saving” into “reinforcement”

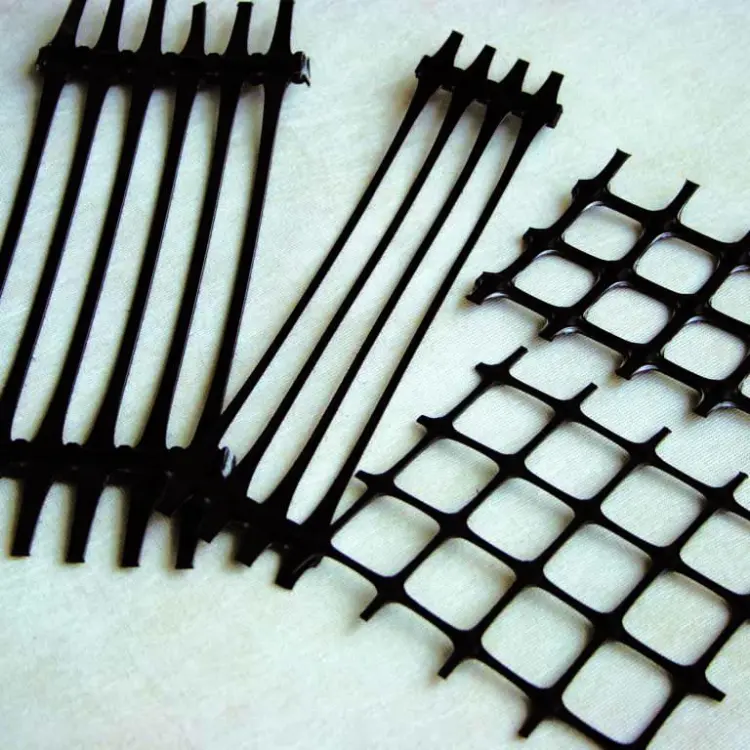

A uniaxial geogrid retaining wall uses high-density polyethylene (HDPE) strips. These strips create an elastic skeleton within the soil. This process makes backfill into self-stabilizing “gravity blocks.” Geogrid walls don’t need formwork or rebar tying. Plus, they skip the long curing time of large concrete volumes. Owners often compare total costs against rubble masonry or reinforced cantilever concrete walls. Here’s a clear cost breakdown for a typical 5 m wall (per linear meter). Following this, you’ll find case data and supplier actions to reduce material costs.

2. Cost breakdown for a 5 m high geogrid wall (per linear meter)

Assumptions:

Wall height: 5.0 m

Top width: 0.8 m

Face slope: 1:0.1

Reinforcement length: 5.0 m (L/H = 1.0)

Geogrid spacing: 0.4 m → 13 layers

Local fill used.

Compaction: ≥ 93%

Materials

Uniaxial geogrid TGDG90: 13 layers × 5 m × 1 m = 65 m²; unit price RMB 4.2 / m² → RMB 273

Connection rods (Φ8 plastic-coated steel): 13 pcs × 5 m × RMB 1.2 / m → RMB 78

Geotextile 200 g/m², filter layer: 5 m × 1 m = 5 m²; RMB 2.0 / m² → RMB 10

Graded crushed stone filter layer: 0.05 m × 5 m × 1 m = 0.25 m³; onsite price RMB 110 / m³ → RMB 28

Bagged planting soil + grass seed (facing greening): 0.1 m × 5 m × 1 m = 0.5 m³ → RMB 45

Materials subtotal: RMB 434 per linear meter

Labor & Machinery

Foundation trench excavation (0.6 m × 0.8 m × 1 m = 0.48 m³): machine + labor RMB 25 / m³ → RMB 12

Layered backfill and compaction (5 m × 5 m × 0.8 m = 20 m³; includes leveling, watering, and compaction): RMB 12/m³ → RMB 240

Geogrid Laying and Connection Rod Installation:

Skilled Worker: 1.2 worker-days × RMB 280/day = RMB 336.

Labor & machinery subtotal: RMB 588 per linear meter

Indirect Costs

Transport (30 km): geogrid 0.9 t → RMB 35

Testing (pullout per layer + compaction checks): allocated RMB 25.

General management fee (3%): (434 + 588 + 60) × 3% ≈ RMB 32

Indirect subtotal: RMB 92 per linear meter

Comprehensive Unit Price

Materials 434 + Labor/Machinery 588 + Indirect 92 = RMB 1,114 per linear meter

Converted to volume: wall cross-section ≈ 4.5 m³ → RMB 248 / m³. This figure is a bit higher than some industry estimates, like RMB 140 / m³ for a 5 m wall. This is because it includes costs for face greening, the filter layer, and testing.

3. Real project — Left Bank, Guangxi River Channel, 8 m reinforced wall

Project length: 186 m

Wall height: 8 m; bottom layer reinforcement length: 10 m, top layer: 6 m; total: 20 layers.

Fill: local red clay, moisture content 22%; improved with 4% quicklime.

Contract model: material subcontract + labor-only package

Final account (2023 Q4):

TGDG120 geogrid: 138,000 m² × RMB 4.5 / m² = RMB 621,000

Connectors, filters, crushed stone, and other consumables: RMB 114,000

Labor (excavation, filling, compaction, laying): RMB 382,000

Transport, testing, management: RMB 73,000

Total: RMB 1,189,000 → RMB 6,400 per linear meter → RMB 102/m³

The first design for a concrete cantilever wall cost around RMB 24,800 per linear meter. The geogrid solution saved around 74%. Compared with a rubble masonry wall at RMB 13,600 per linear meter, savings were approximately 53%.

4. How Hengshui Aohong drives down owners’ costs

4. How Hengshui Aohong drives down owners’ costs

Hengshui Aohong cuts costs for uniaxial geogrid retaining walls. They use smart strategies for raw materials. They control processes and increase manufacturing scale. Also, they offer value-added services.

Raw material scale and locked pricing

We buy 42,000 tons of HDPE resin each year. We do this by signing quarterly contracts with big suppliers like Sinopec and LyondellBasell. This method reduces raw material prices. They are about RMB 180 per ton lower than those from smaller manufacturers. We pass this advantage on to customers as a discount of roughly RMB 0.3/m² on geogrid.

Three-stage temperature control during uniaxial stretching.

Separate PID control zones for plasticization, preheating, and stretching. This keeps the stretch ratio stable at 9.5–10.0. The strip’s molecular orientation increases by about 6%. So, a TGDG120 rated at 120 kN/m shows an average strength of 128 kN/m. Customers pay for 120 kN/m but effectively receive an extra ~8% safety margin.

6 m wide jumbo rolls

Standard market widths are 2–3 m; Aohong produces 6 m wide rolls, reducing longitudinal overlaps by ~15%. For a 186 m wall, this cuts 28 seams, saves ~22 worker-days, equal to ~RMB 11,000 in labor savings.

On-delivery pull-out and site-adapted reports

For every 5,000 m² shipped, Aohong provides a soil-adaptation and pullout report. This report recommends the best vertical spacing and helps avoid unnecessary densification. In the Guangxi project, we changed the recommended spacing from 0.35 m to 0.40 m. This cut the geogrid quantity by 11% and saved RMB 68,000 on materials.

Capacity and lead times

Two uniaxial production lines produce 280,000 m² per day. Standard specs ship in 48 hours. Rush cutting and palletizing can happen in 24 hours. This helps meet rainy season backfill deadlines.

Closed-loop recycling

They crush and regranulate trim waste and edge scrap online. The reuse rate is about 8%. This cuts costs and helps with green product certification. It also aids owners in earning a “green construction” score in bids.

5. Summary & design guidance

The main factor in the cost of uniaxial geogrid retaining walls is the geogrid. Labor and management costs follow closely behind.

Alternate search names:

Uniaxial geogrid wall costs.

Uniaxial geogrid-reinforced wall costs.

HDPE geogrid retaining wall costs.

TGDG geogrid wall costs.

Key supplier strategies include:

Large-scale resin procurement

Process controls to boost strip strength.

Wider roll widths to cut overlaps.

Delivered pull-out reports for better spacing.

On-site testing

These tactics can lower primary material prices by 12–15% below the market average. They can also reduce total project costs to around RMB 100–120 per m³.

When “cost-saving” and “low carbon” are key criteria, data-backed proposals stand out.

These include:

Traceable material origins

Tested pull-out results

Actual spacing optimization

A reusable waste policy

They make their bids more persuasive.

To budget and buy wisely, compare the total costs of uniaxial geogrid retaining walls. Include materials, labor, and management. Include testing and greening. A good supplier can turn “reinforcement” into real cost savings and useful environmental credits.

1. Translate “cost-saving” into “reinforcement”

1. Translate “cost-saving” into “reinforcement” 4. How Hengshui Aohong drives down owners’ costs

4. How Hengshui Aohong drives down owners’ costs